- +86 15725667691

- rentianyu2022@foxmail.com

- Zhucheng City, Shandong Province,CN

No products in the cart.

For more than two decades, we have blended process R&D, precision manufacturing and global project management to help beverage, ready-meal and snack plants launch efficient production lines. The figures below reflect Anxu’s strengths across every critical stage.

Eight Turnkey Solutions for Diverse Food-Processing Needs

Washing, peeling, slicing, continuous frying & IQF freezing—stable 50–1000 kg/h throughput.

Bubble washing, pulping, vacuum concentration, UHT & aseptic filling with full CIP.

Cutting, sous-vide, rapid chilling & MAP packing for standardized, high-volume meals.

70 % less oil at low-temp vacuum; preserves colour, flavour & nutrients for premium crisps.

−40 °C freeze-drying keeps 98 % nutrients—ideal for pet food, outdoor & space snacks.

Braising, smoking, tumbling & filling integrated for cooked meats, sausages & hams.

Continuous pre-cook, canning, sealing and retort sterilizing for commercial sterility.

VFFS, case packing, check-weighing & robotic palletizing for fully automated dispatch.

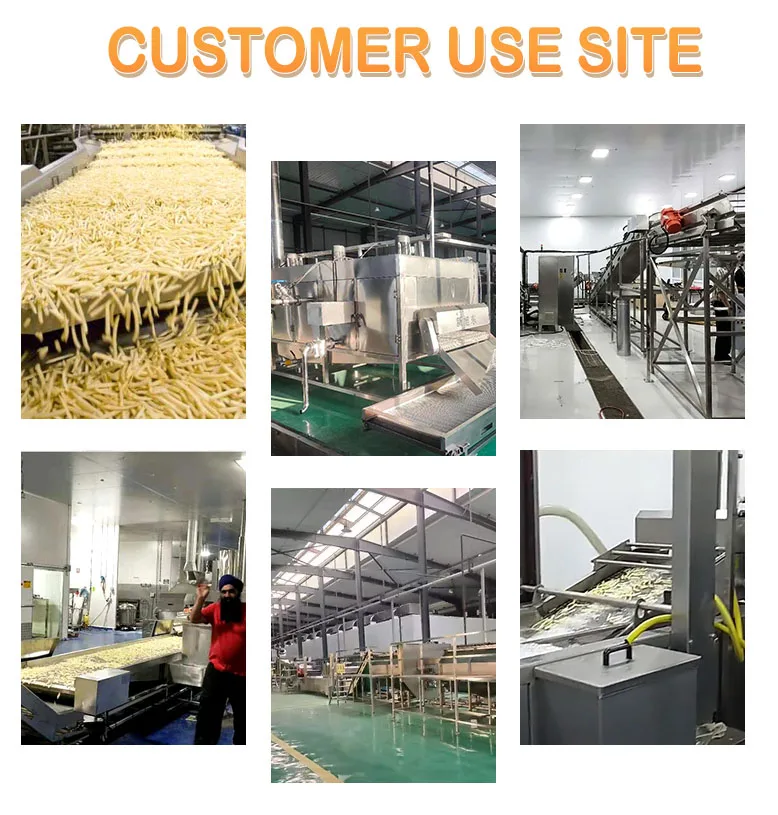

From Latin America to Europe and Southeast Asia, Anxu has delivered turnkey lines to 60 + countries.

Showcase our capability across chips & fries, juice, ready-meals, vacuum frying, freeze-drying and canning.

Share your raw materials, recipe and capacity target—receive a tailored proposal and exact quote within 24 hours.

The turnkey production line is installed and run within 9 days.

Vacuum concentration & tubular UHT with 24 h CIP-SIP.

Cutting, sous-vide & MAP packing integrated; 40 % labour saved.

Turnkey food processing equipment—chips & fries lines, vacuum fryers, freeze dryers, fruit & veg wash-sterilize systems.

© 2023 Created with Shandong Anxu Machinery Technology Co., Ltd.